Why High-Pressure Die Casting Delivers Unmatched Performance in Cast Aluminum

You see high-pressure die casting setting the standard in cast aluminum manufacturing. This process dominates the industry, holding over 78% revenue share in 2024. Many sectors, especially automobile manufacturing, rely on it to create lightweight, precise parts that improve fuel efficiency and performance.

Key Takeaways

- High-pressure die casting produces strong, precise aluminum parts quickly, making it ideal for high-volume manufacturing with complex designs.

- This process creates lightweight parts with excellent surface finish and tight tolerances, reducing the need for extra finishing work.

- Advanced technology and quality control in die casting improve product consistency, lower costs, and support sustainable manufacturing practices.

What Makes High-Pressure Die Casting Unique for Cast Aluminum

The High-Pressure Die Casting Process

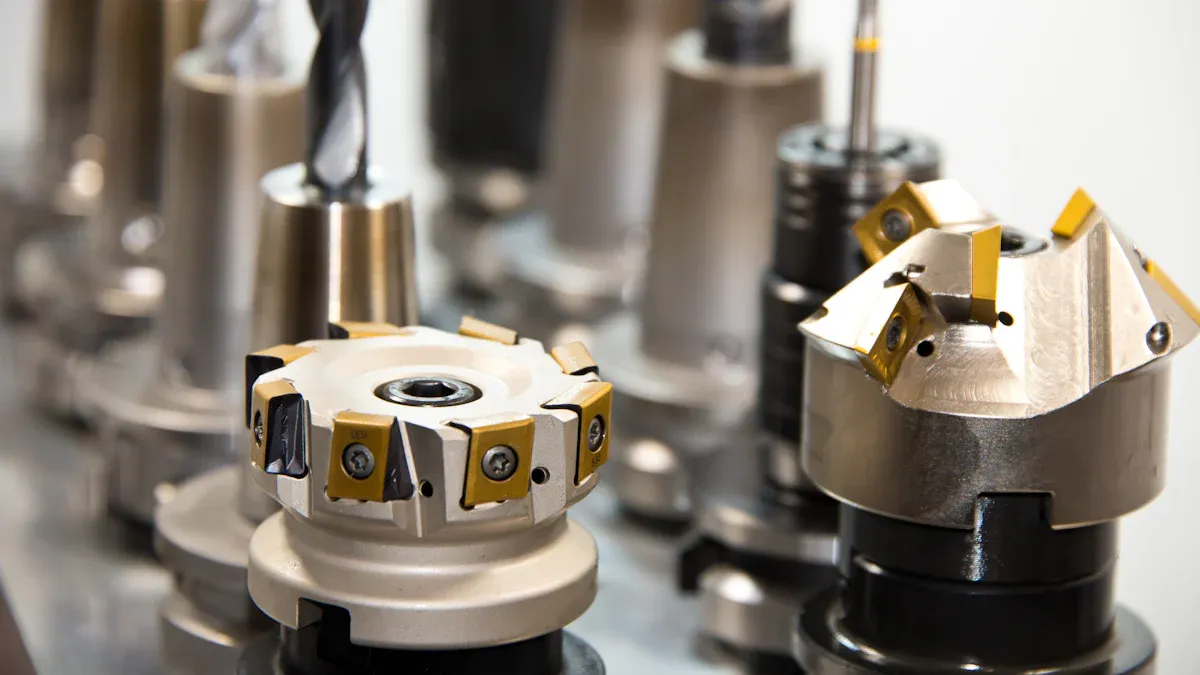

You start the high-pressure die casting process by preparing the steel mold. Workers clean and lubricate the mold to help control temperature and make it easier to remove the finished part. Next, you melt the aluminum alloy in a furnace. You then transfer the molten metal into a shot sleeve, usually in a cold chamber system because aluminum melts at a high temperature. A piston injects the molten aluminum into the closed mold at very high pressure—sometimes up to 1200 bar. The metal fills every detail of the mold quickly and solidifies under pressure. Once the part cools, ejector pins push it out of the mold. Finally, you trim away any extra material. This process lets you create cast aluminum parts with thin walls and complex shapes in just seconds.

Distinct Advantages Over Other Casting Methods

High-pressure die casting stands out from other methods because of its speed, precision, and ability to make detailed parts. You can see the differences clearly in the table below:

| Feature | High-Pressure Die Casting (HPDC) | Other Aluminum Casting Methods |

|---|---|---|

| Injection Pressure | Very high (700–2500 bar) | Much lower (0.7–1.5 bar) |

| Cycle Time | Very fast (seconds) | Slower (minutes) |

| Wall Thickness | Thin (0.4–1 mm) | Thicker |

| Dimensional Accuracy | Excellent | Good, but less precise |

| Surface Finish | Excellent | Good, may need more finishing |

| Production Suitability | High-volume, complex parts | Lower volume, simpler parts |

You benefit from rapid production and high repeatability. The process gives you tight tolerances and smooth surfaces, which means less finishing work. High-pressure die casting is ideal when you need large numbers of cast aluminum parts that are both strong and detailed.

Performance Benefits of High-Pressure Die Casting in Cast Aluminum

Precision and Consistency

You gain a major advantage with high-pressure die casting when you need precise and consistent cast aluminum parts. This process uses strong steel molds and high injection pressure, which lets you create parts with complex shapes and fine details. You can achieve thin walls and tight tolerances, which is difficult with other casting methods. For example, sand casting often leaves rough surfaces and thicker walls, while die casting produces smoother finishes and more accurate dimensions.

| Feature | Die Casting | Sand Casting |

|---|---|---|

| Geometry Complexity | High; intricate and fine details achievable | Limited; simpler designs preferred |

| Wall Thickness | Thin walls possible (supports lightweight parts) | Thicker walls due to mold limitations |

| Dimensional Accuracy | High; less need for finishing operations | Lower; often requires additional finishing |

| Surface Finish | Smooth, high quality | Rougher, textured by sand molds |

You can see that die casting stands out for its ability to deliver consistent results, especially when you need thousands of identical cast aluminum components. While the process alone cannot always reach the tightest tolerances (like ±0.01 mm), you can use CNC machining after casting to achieve these exact measurements. Regular inspection and careful process control help you maintain high quality from part to part.

Tip: If you want the best surface finish and dimensional accuracy for your cast aluminum parts, high-pressure die casting is the top choice.

Mechanical Strength and Durability

When you choose high-pressure die casting, you get cast aluminum parts with impressive mechanical strength and durability. The rapid cooling during the process creates a fine-grained microstructure, which boosts both strength and surface quality. You benefit from aluminum’s high strength-to-weight ratio, making it perfect for lightweight yet tough components.

- High-pressure injection reduces defects like porosity and shrinkage, so your parts last longer.

- Aluminum’s excellent thermal conductivity helps your parts handle heat, which is important for automotive and electronic uses.

- The fine grain structure from rapid solidification increases both ductility and resistance to cracking.

For example, certain HPDC aluminum alloys can reach yield strengths up to 321 MPa and ultimate tensile strengths of 425 MPa after heat treatment. These numbers show that you can rely on cast aluminum parts for demanding jobs, from car engines to aerospace frames.

Cost Efficiency and Productivity

You save time and money with high-pressure die casting. The process allows you to produce large numbers of cast aluminum parts quickly, thanks to fast cycle times and reusable molds. You can make complex shapes in seconds, which means you respond faster to market needs.

- Automated systems and advanced mold designs reduce defects and downtime.

- You often need less machining and finishing, which lowers your overall costs.

- Real-world examples show up to 20% shorter manufacturing cycles and 30% lower production costs for some products.

| Post-Processing Step | Description | Impact on Production Time and Quality |

|---|---|---|

| Trimming and Deburring | Removes excess material for smooth surfaces | Essential for tight tolerances and quality |

| Precision Machining | Achieves critical tolerances and assembly readiness | Adds time but ensures specifications are met |

| Heat Treatment | Improves strength and ductility | Increases durability, especially for tough uses |

You can see that while some post-processing is needed, the overall speed and efficiency of high-pressure die casting make it a smart choice for high-volume cast aluminum production.

Environmental and Sustainability Advantages

You help the environment when you use high-pressure die casting for cast aluminum parts. The process supports recycling and reduces waste, which is important for sustainable manufacturing.

- You can use recycled aluminum alloys, which saves up to 95% of the energy compared to making new aluminum from ore.

- The process produces less scrap because of its precision, and you can remelt and reuse trim scrap.

- Aluminum’s light weight means products like cars and planes use less fuel, lowering emissions over their lifetime.

- Many manufacturers use energy-efficient furnaces and renewable energy sources to further cut down on carbon emissions.

Note: By choosing high-pressure die casting, you support a circular economy and help meet global sustainability goals.

Achieving Excellence in Cast Aluminum with Advanced Technology

Role of Modern Equipment and Automation

You achieve higher quality and efficiency in cast aluminum production by using modern equipment and automation. Today’s die casting machines use sensors and real-time monitoring to adjust process parameters instantly. This technology helps you reduce errors and maintain consistent results. Automation also brings robotic ladles and handling systems into your workflow. These robots improve workplace safety and ensure each part meets strict standards.

You benefit from several recent advancements:

- Sensors in machines allow real-time adjustments, reducing mistakes.

- Simulation software helps you design better molds and predict outcomes.

- Vacuum-assisted and extrusion die casting methods improve surface finish and product quality.

- Robotic systems handle dangerous tasks, keeping your team safe.

- Energy-efficient motors and mist covers lower costs and support sustainability.

- IIoT (Industrial Internet of Things) connects your machines for smart manufacturing, predictive maintenance, and quick process changes.

With these tools, you can produce cast aluminum parts faster, with fewer defects, and at a lower cost.

Importance of Quality Control and Assurance

You must focus on quality control to deliver reliable cast aluminum components. Real-time monitoring systems track key factors like temperature, pressure, and cycle time. These systems let you spot problems early and make quick corrections. Automated vision inspection and thermal imaging catch defects before they reach customers.

Quality control in high-pressure die casting often follows strict industry standards. For example, automotive and aerospace parts require IATF 16949 and ISO 9001 certifications. You use several methods to ensure quality:

| Quality Control Step | Description |

|---|---|

| Pre-Production Planning | Risk analysis, process validation, capability studies |

| In-Process Control | Real-time monitoring, SPC, automated inspections |

| Post-Production Testing | X-ray, CT scans, pressure and hardness testing |

Advanced inspection tools like X-ray and CT scanning reveal hidden defects inside cast aluminum parts. These technologies help you find voids or cracks that you cannot see from the outside. By using these methods, you improve product reliability and meet the highest industry standards.

You set the standard for cast aluminum components when you choose high-pressure die casting. Research shows this process delivers unmatched strength, precision, and reliability. Manufacturers prefer it for rapid cycles, thin-walled parts, and consistent quality.

- Rapid production cycles

- High dimensional accuracy

- Superior mechanical properties

FAQ

What industries use high-pressure die casting for aluminum parts?

You find high-pressure die casting in automotive, electronics, aerospace, and consumer goods. These industries need lightweight, strong, and precise aluminum components.

How does high-pressure die casting improve part quality?

You get better part quality because the process uses high pressure and steel molds. This creates smooth surfaces, tight tolerances, and fewer defects.

Can you recycle aluminum used in high-pressure die casting?

Yes! You can recycle aluminum scrap from the process. Recycling saves energy and supports sustainable manufacturing.