What Drives the Popularity of Precision Aluminum Casting Gear Boxes Housing in 2025

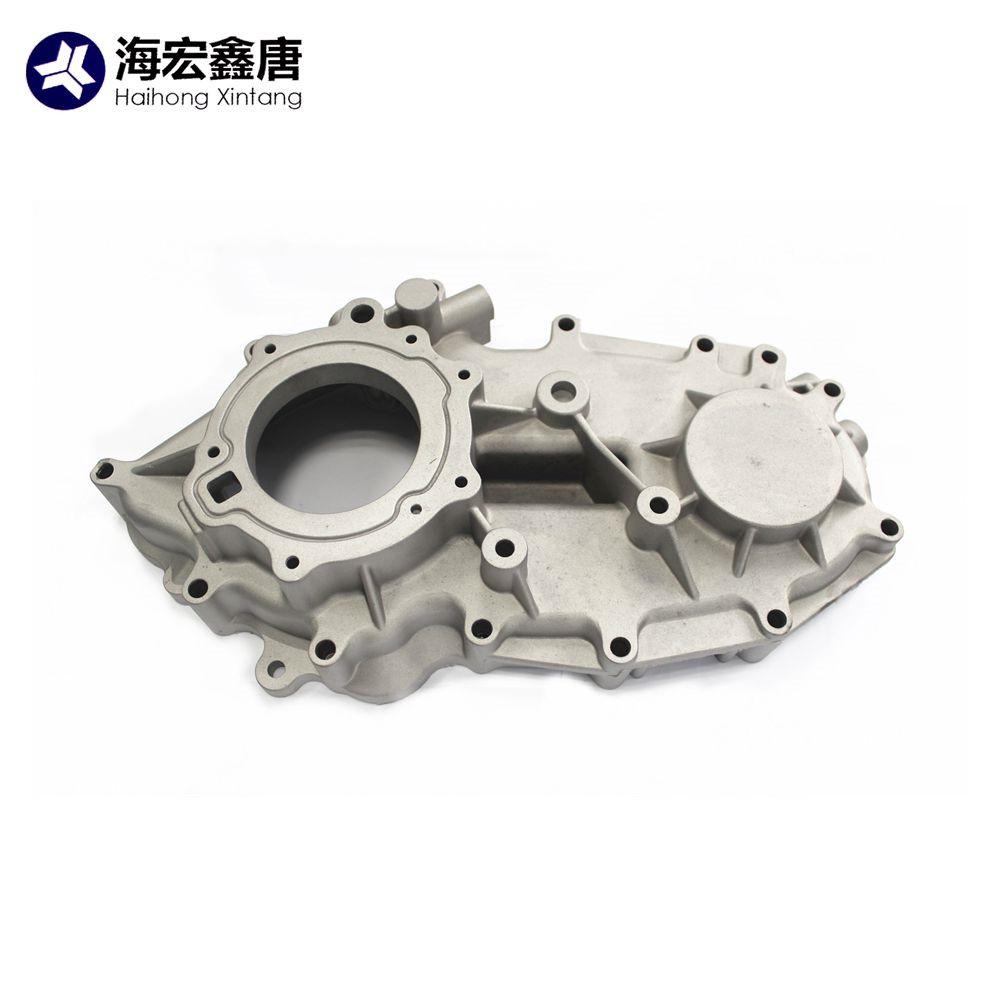

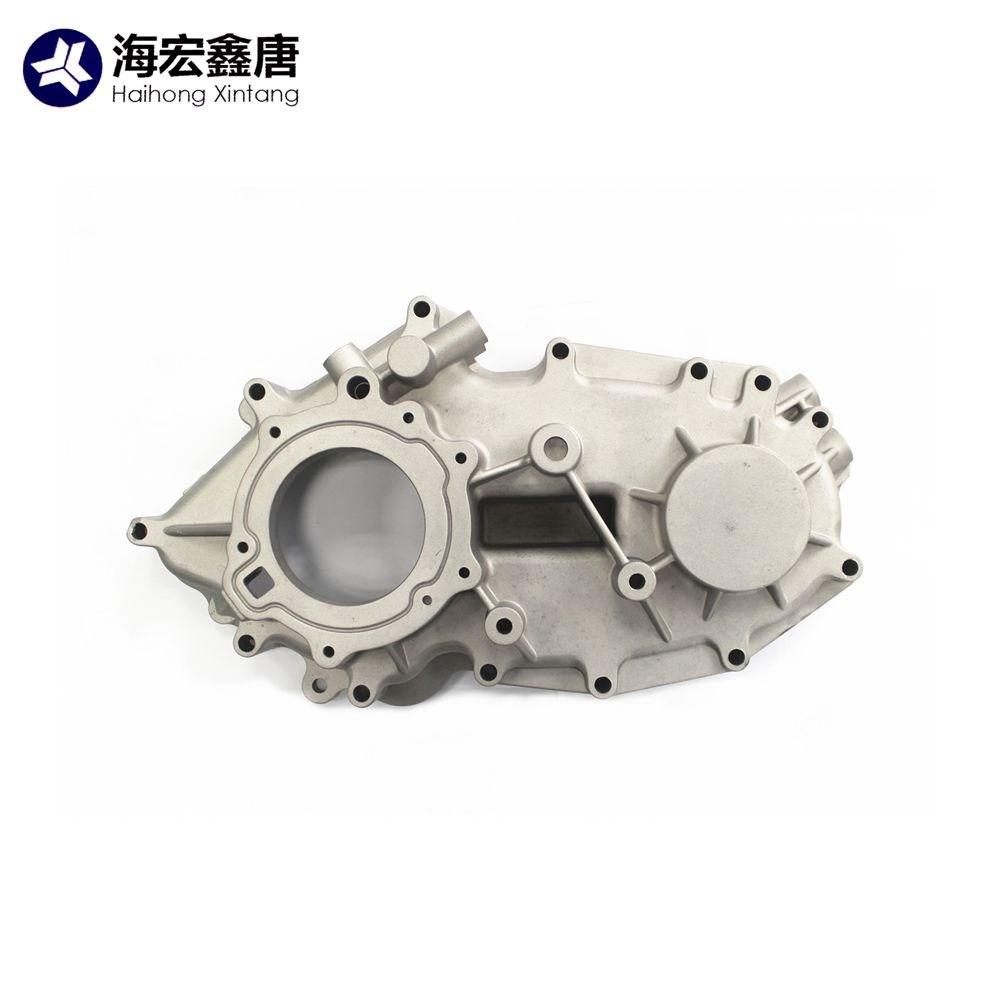

Precision aluminum casting gear boxes housing lead the market in 2025. Engineers choose these housings for their lightweight strength and impressive durability. The Customized high precision aluminum casting process allows manufacturers to create parts that fit exact needs. Aluminum casting gear boxes housing also resist corrosion, which helps them last longer in harsh environments. Many industries value these qualities because they want reliable and cost-effective solutions.

Key Takeaways

- Precision aluminum casting gear box housings combine light weight and strong durability, improving vehicle speed and fuel efficiency.

- These housings resist corrosion well, which extends their lifespan and lowers maintenance costs in harsh environments.

- Advanced manufacturing methods ensure exact sizes and stable structures, leading to smooth gear operation and fewer defects.

- Custom designs and material choices allow perfect fits for different industries, reducing assembly time and repair needs.

- Using these housings saves money over time by cutting shipping costs, minimizing waste, and reducing machine downtime.

Key Performance Benefits of Precision Aluminum Casting Gear Boxes Housing

Lightweight Strength for Demanding Applications

Precision aluminum casting gear boxes housing offer a unique combination of lightness and strength. Engineers select these housings for vehicles and machines that need to move quickly or carry heavy loads. Aluminum alloys, such as ADC12 and A380, provide high strength while keeping the weight low. This feature helps cars like the Toyota Corolla and Audi R8 achieve better fuel efficiency and faster acceleration.

Tip: Lighter gear box housings reduce the overall weight of a vehicle. This change can improve both speed and energy savings.

Manufacturers like HHXT use advanced casting methods to create thin-walled designs without sacrificing durability. These housings handle tough conditions in automotive, aerospace, and industrial settings. The result is a product that supports high performance in demanding environments.

Superior Corrosion Resistance

Aluminum resists rust and corrosion much better than many other metals. Precision aluminum casting gear boxes housing last longer because they do not break down easily when exposed to water, salt, or chemicals. This property makes them ideal for cars, trucks, and machines that operate outdoors or in harsh climates.

Surface treatments, such as anodizing and powder coating, add extra protection. HHXT offers several finishing options to meet different needs. These treatments help the gear box housing maintain its appearance and function over time.

- Benefits of corrosion resistance:

- Longer service life

- Lower maintenance costs

- Reliable performance in tough environments

High Dimensional Precision and Stability

Precision aluminum casting gear boxes housing deliver exact shapes and sizes. Manufacturers use high-pressure die casting and CNC machining to achieve tight tolerances. This process ensures that each housing fits perfectly with other parts in the gear system.

Accurate dimensions mean less vibration and noise during operation. The gear box housing stays stable even under heavy loads or high speeds. HHXT checks each product with strict inspections to guarantee quality and consistency.

| Feature | Benefit |

|---|---|

| Tight tolerances | Smooth gear operation |

| Stable structure | Less wear and tear |

| Consistent quality | Fewer defects and failures |

These advantages make precision aluminum casting gear boxes housing a top choice for industries that demand reliability and accuracy.

Cost-Effectiveness and Long-Term Value

Manufacturers and engineers look for solutions that save money and last a long time. Precision aluminum casting gear boxes housing offer both. These housings use less material because aluminum is lightweight but strong. This feature lowers shipping costs and makes handling easier in factories.

HHXT uses advanced casting and machining methods. These methods reduce waste and improve efficiency. Companies do not need to spend extra money on repairs or replacements because the housings resist corrosion and wear. The long service life means fewer breakdowns and less downtime for machines.

Note: Choosing a durable housing helps companies avoid unexpected costs in the future.

Many industries see value in the ability to customize gear box housings. HHXT provides OEM and ODM services. Customers can order housings that fit their exact needs. This flexibility reduces the need for extra parts or adjustments during assembly.

A comparison table shows the main ways these housings save money:

| Feature | Cost Benefit |

|---|---|

| Lightweight material | Lower shipping costs |

| High corrosion resistance | Fewer replacements needed |

| Precise manufacturing | Less waste, fewer defects |

| Customization options | No extra fitting required |

| Long service life | Reduced maintenance expenses |

Companies that invest in precision aluminum casting gear boxes housing gain long-term value. They spend less on repairs and replacements. Their machines run smoothly for years. This smart investment supports growth and keeps operations efficient.

Advanced Manufacturing Processes for Precision Aluminum Casting Gear Boxes Housing

High-Pressure Die Casting Technology

High-pressure die casting stands as a leading method for making gear box housings. This process uses strong machines to force molten aluminum into steel molds. The molds shape the metal with great accuracy. Companies like HHXT use this technology to create parts that have smooth surfaces and exact sizes. The process works quickly and produces many parts in a short time. Workers can make thin walls and complex shapes that fit modern vehicles. High-pressure die casting also helps reduce waste because it uses just the right amount of material.

Rigorous Quality Control and Certification

Quality control plays a key role in making sure each gear box housing meets high standards. HHXT checks every product at several steps during production. Inspectors look for cracks, size errors, or other problems. They use special tools to measure each part. The company follows strict rules set by ISO9001:2008 and IATF16949. These certifications show that the factory meets global standards for quality and safety. Customers trust products that pass these tests because they know the parts will work well in their machines.

Tip: Certified products often last longer and perform better in tough conditions.

Design Flexibility and Customization

Manufacturers can change the design of precision aluminum casting gear boxes housing to fit many needs. They use computer drawings and advanced machines to make custom shapes and sizes. HHXT offers both OEM and ODM services. Customers can send their own designs or samples. The factory then creates gear box housings that match these requests. This flexibility helps car makers and other industries get parts that fit perfectly. Customization also means companies do not need to make extra changes during assembly.

- Benefits of customization:

- Perfect fit for each project

- Faster assembly times

- Fewer mistakes during installation

Material Grades Used in Precision Aluminum Casting Gear Boxes Housing

Common Aluminum Alloys and Their Properties

Manufacturers choose specific aluminum alloys for gear box housings because each alloy offers unique benefits. ADC1, ADC12, A380, and AlSi9Cu3 are some of the most popular choices. These alloys combine strength, light weight, and resistance to corrosion.

- ADC1: This alloy provides good castability and high resistance to corrosion. It works well in environments where moisture or chemicals are present.

- ADC12: Many automotive companies use ADC12. It offers excellent mechanical strength and good thermal conductivity. This alloy also resists wear, which helps gear boxes last longer.

- A380: A380 stands out for its balance of strength and fluidity. It allows for complex shapes and thin walls. This alloy also keeps its strength at high temperatures.

- AlSi9Cu3: This alloy contains silicon and copper. It gives high strength and good machinability. AlSi9Cu3 also provides a smooth surface finish after casting.

Tip: The right alloy can improve both the performance and the lifespan of a gear box housing.

Application-Specific Material Selection

Engineers select alloys based on the needs of each application. For example, automotive gear boxes often require materials that handle high stress and frequent use. ADC12 and A380 fit these needs because they combine durability with light weight. Aerospace applications may need even lighter materials, so engineers might choose alloys with higher silicon content for extra strength and reduced weight.

Industrial machines sometimes operate in harsh environments. In these cases, alloys like ADC1 offer better corrosion resistance. The choice of alloy affects how well the gear box housing performs over time. Companies like HHXT help customers pick the best material for their specific project.

A simple table shows how different alloys match different needs:

| Alloy | Best For | Key Benefit |

|---|---|---|

| ADC1 | Corrosive environments | High corrosion resistance |

| ADC12 | Automotive gear boxes | Strength and durability |

| A380 | Complex shapes | Fluidity and strength |

| AlSi9Cu3 | Precision parts | Machinability and finish |

Choosing the right alloy ensures the gear box housing meets all performance and safety requirements.

Real-World Applications of Precision Aluminum Casting Gear Boxes Housing

Automotive Industry Success Stories

Automotive companies rely on advanced gear box housings to improve vehicle performance. Brands like Toyota and Audi use high-precision aluminum parts in popular models such as the Corolla, R8, Q7, and TT. These housings help cars run smoothly and last longer. Engineers choose aluminum because it keeps vehicles light and strong. Lighter cars use less fuel and move faster. HHXT supplies custom gear box housings that fit exact car models. This approach helps car makers meet strict safety and quality standards.

Note: Custom-fit housings reduce the risk of part failure and make repairs easier for mechanics.

Aerospace and High-Performance Sectors

The aerospace industry demands parts that can handle extreme conditions. Aircraft need gear box housings that resist corrosion and stay stable at high speeds. Aluminum alloys, like those used by HHXT, provide the right mix of strength and lightness. Engineers design these housings to fit tight spaces in planes and helicopters. High-precision casting allows for complex shapes that save space and weight. This technology helps aircraft fly farther and use less fuel.

A table shows some key benefits for aerospace:

| Feature | Benefit |

|---|---|

| Lightweight | Better fuel savings |

| Strong alloys | Improved safety |

| Custom design | Fits unique spaces |

Industrial Machinery and Equipment

Factories and workshops use machines that run for many hours each day. These machines need gear box housings that can handle heavy loads and constant motion. Aluminum housings resist rust and wear, even in tough environments. HHXT offers solutions for many types of industrial equipment. Customization lets companies order housings that match their machines perfectly. This reduces downtime and keeps production lines moving.

Tip: Choosing the right housing helps factories avoid costly repairs and lost time.

Precision aluminum casting gear boxes housing lead the market in 2025. Many industries choose these housings for their strong performance and cost savings. Advanced manufacturing methods and a wide range of materials help meet the needs of automotive, aerospace, and industrial sectors. Companies gain long-term durability and efficiency.

Choosing these housings gives businesses a real advantage in today’s competitive world.

FAQ

What makes aluminum casting gear box housings popular in 2025?

Aluminum casting gear box housings offer strength, light weight, and corrosion resistance. Many industries choose them for their durability and cost savings. Companies like HHXT use advanced technology to create precise and reliable parts.

Which industries use precision aluminum casting gear box housings?

Automotive, aerospace, and industrial machinery sectors use these housings. Car makers like Toyota and Audi rely on them for performance and efficiency. Factories and workshops also benefit from their long-lasting quality.

How does HHXT ensure product quality?

HHXT performs over six inspections on each housing. The company follows ISO9001:2008 and IATF16949 standards. These steps guarantee that every product meets strict quality requirements.

Can customers request custom designs or sizes?

Yes! Customers can send 2D or 3D drawings or samples. HHXT offers OEM and ODM services. The team creates gear box housings that match exact needs, ensuring a perfect fit for every project.