How does CNC machining improve the precision of spare parts?

CNC machining transforms spare parts production by ensuring unmatched precision. You can rely on this process to eliminate human error and achieve consistent quality across every piece. By using advanced programming and automation, CNC machines follow exact specifications, delivering results that meet tight tolerances. Whether creating intricate designs or optimizing manufacturing processes, CNC machining offers reliable solutions. Industries like OEM aluminum die casting benefit from the ability to produce flawless components, such as die casting motorcycle covers, at competitive prices. In particular, china OEM aluminum die casting has become a key player in delivering high-quality products while maintaining cost-effectiveness, especially when it comes to die casting motorcycle cover price.

Key Takeaways

- CNC machining removes human mistakes, making parts with great accuracy.

- Automation lets CNC machines work nonstop without getting tired. This saves time and materials while staying precise.

- Multi-axis machines can make tricky designs that old methods can’t. This ensures parts fit perfectly in assemblies.

- Good cutting tools are important for smooth cuts and exact sizes. This improves how the final product works.

- Real-time monitors give quick updates during production to catch mistakes early and keep quality steady.

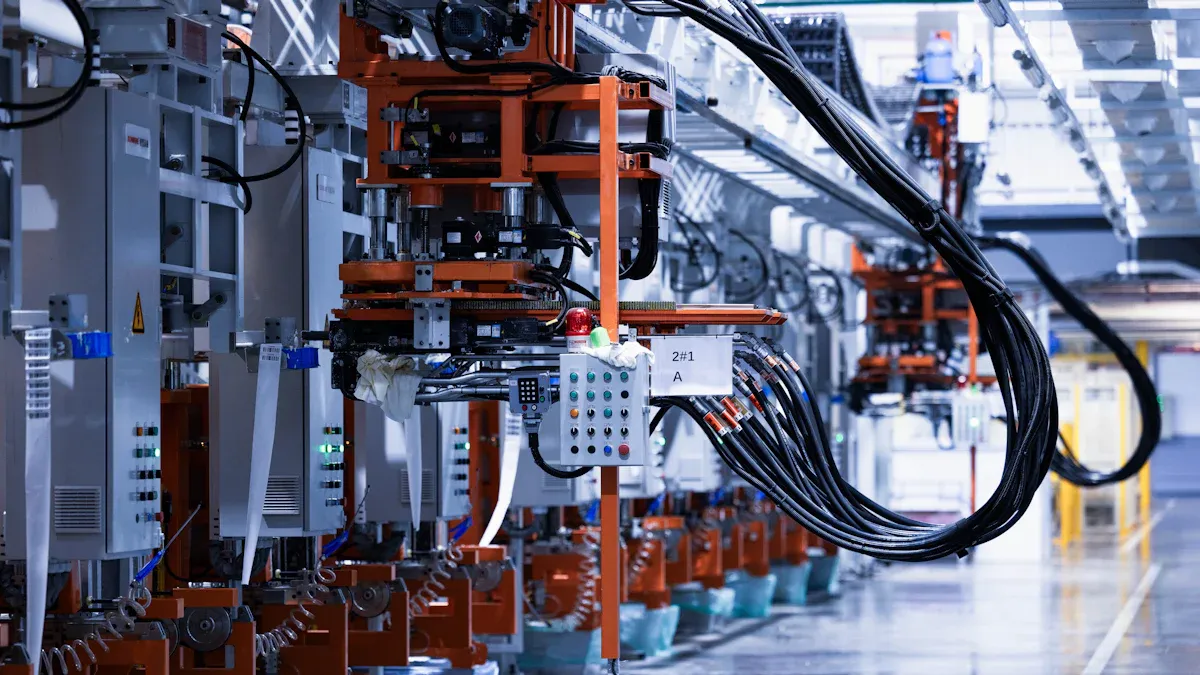

Core Mechanisms of Precision in CNC Machining

Automation and its role in reducing human error

Automation plays a critical role in CNC machining by eliminating the inconsistencies caused by manual operations. When you rely on automated systems, the machine executes every step of the process with exact precision. This reduces the chances of mistakes that often occur when humans perform repetitive tasks.

Tip: Automation ensures that every spare part produced matches the original design, even in large-scale production.

CNC machines follow pre-programmed instructions, which means you don’t need to worry about variations between parts. The process also allows for continuous operation without fatigue, ensuring consistent quality. For example:

- Repetitive tasks like drilling or cutting are performed with the same accuracy every time.

- Complex operations are handled with ease, as the machine doesn’t deviate from its programmed path.

By reducing human involvement, automation not only improves precision but also saves time and resources.

Multi-axis capabilities for complex geometries

CNC machines with multi-axis capabilities can handle intricate designs that would be impossible with traditional methods. These machines move in multiple directions, allowing you to create parts with complex shapes and angles.

Imagine trying to carve a 3D object by hand. It would take hours, and the results might not be perfect. Multi-axis CNC machines solve this problem by offering:

- 3-axis machining for basic operations like drilling and milling.

- 5-axis or more for advanced tasks, such as creating curved surfaces or undercuts.

Note: Multi-axis machining is essential for industries like aerospace and automotive, where precision and complexity go hand in hand.

With these capabilities, you can produce spare parts that fit perfectly into intricate assemblies. This ensures that every component works seamlessly with the rest of the system.

CAD/CAM software for accurate design-to-production translation

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software bridge the gap between your ideas and the final product. These tools allow you to design parts with incredible detail and then convert those designs into machine-readable instructions.

When you use CAD/CAM software, you gain several advantages:

- Precision in design: You can create detailed 3D models with exact dimensions.

- Seamless integration: The software ensures that the design translates perfectly into the machining process.

- Error detection: It identifies potential issues before production begins, saving you time and material.

For example, if you’re designing a spare part with tight tolerances, CAD/CAM software ensures that every measurement is accurate. The machine then follows these instructions to produce a part that matches your specifications exactly.

Fun Fact: CAD/CAM software can simulate the machining process, allowing you to see how the part will look before it’s even made.

By combining advanced software with CNC machining, you can achieve a level of precision that was once unimaginable.

Technological Features Enhancing Precision

High-quality cutting tools and their impact on accuracy

The cutting tools you choose play a vital role in determining the precision of CNC machining. High-quality tools ensure clean cuts, reduce material deformation, and maintain tight tolerances. When you use subpar tools, the results often include rough edges, dimensional inaccuracies, and increased wear on the machine.

Here’s why high-quality cutting tools matter:

- Sharper edges: These tools cut through materials cleanly, leaving smooth surfaces.

- Durable materials: Tools made from carbide or diamond last longer and resist wear, ensuring consistent performance.

- Reduced vibration: High-quality tools minimize vibrations, which can cause inaccuracies during machining.

Tip: Regularly inspect and replace cutting tools to maintain precision. Worn-out tools can compromise the quality of your spare parts.

For example, if you’re machining aluminum components, using a tool with a polished cutting edge prevents burrs and ensures a flawless finish. This attention to detail directly impacts the performance and reliability of the final product.

Material selection and its influence on machining precision

The material you select for machining significantly affects the precision of the final product. Different materials have unique properties, such as hardness, ductility, and thermal conductivity, which influence how they respond to cutting forces.

Consider these factors when choosing materials:

- Hardness: Harder materials, like stainless steel, require specialized tools and slower cutting speeds to achieve precision.

- Thermal expansion: Materials that expand under heat, such as plastics, need careful temperature control during machining.

- Machinability: Some materials, like aluminum, are easier to machine and produce more accurate results compared to tougher alloys.

Note: Always match the material to the application. For instance, aerospace components often require lightweight yet durable materials like titanium, which demand precise machining techniques.

By understanding the properties of your chosen material, you can optimize the machining process to achieve the highest level of accuracy.

Real-time monitoring and feedback systems

Real-time monitoring systems revolutionize CNC machining by providing instant feedback during the production process. These systems track variables like cutting speed, tool wear, and machine vibrations, ensuring that every operation stays within the desired parameters.

Here’s how real-time monitoring enhances precision:

- Error detection: Sensors identify deviations from the programmed path and alert you immediately.

- Tool condition monitoring: The system tracks tool wear and recommends replacements before quality is compromised.

- Adaptive adjustments: Machines can automatically adjust cutting speeds or feed rates to maintain accuracy.

Fun Fact: Some advanced CNC machines use AI-powered monitoring systems to predict potential issues before they occur.

For example, if a tool begins to wear out during production, the monitoring system can pause the operation and notify you. This prevents defects and ensures that every spare part meets your specifications.

By leveraging real-time monitoring, you can maintain consistent quality and reduce the risk of errors, even in high-volume production.

Benefits of Precision in Spare Parts

Consistency in manufacturing for large-scale production

Precision in CNC machining ensures that every spare part you produce matches the original design, even in high-volume manufacturing. This consistency is critical when you need to meet tight deadlines or deliver large quantities of parts without compromising quality.

When you rely on CNC machining, the process eliminates variations between parts. Each component is identical, ensuring seamless integration into larger assemblies. For example:

- Automotive parts: Every gear or engine component fits perfectly, reducing assembly time.

- Electronics: Circuit boards maintain uniformity, ensuring reliable performance.

Tip: Consistency in manufacturing builds trust with your customers, as they can depend on you for reliable, high-quality products.

By maintaining uniformity, CNC machining helps you scale production while meeting industry standards.

Reduced defects and waste, leading to cost efficiency

Defects and material waste can significantly increase production costs. CNC machining minimizes these issues by following precise instructions and using advanced monitoring systems. This ensures that each part meets your specifications without errors.

Here’s how precision reduces waste:

- Accurate cuts: The machine removes only the necessary material, leaving no excess.

- Error prevention: Real-time monitoring detects issues early, preventing defective parts.

Fun Fact: Companies using CNC machining often report up to a 30% reduction in material waste compared to traditional methods.

By reducing defects, you save on raw materials and rework costs. This efficiency translates into higher profits and a more sustainable production process.

Compatibility with intricate and custom designs

CNC machining excels at producing parts with complex geometries and custom specifications. Whether you’re creating intricate patterns or unique designs, the process ensures that every detail is accurate.

For instance, if you need a spare part with tight tolerances or unusual shapes, CNC machines can handle the challenge. Multi-axis capabilities allow you to create undercuts, curved surfaces, and other intricate features with ease.

Note: Custom designs are especially valuable in industries like aerospace, where precision and innovation go hand in hand.

By offering compatibility with intricate designs, CNC machining empowers you to meet specialized requirements without sacrificing quality.

OEM Aluminum Die Casting and CNC Machining

How CNC machining enhances precision in aluminum die casting

CNC machining plays a vital role in improving the precision of aluminum die casting. When you combine CNC machining with die casting, you gain the ability to refine components to meet exact specifications. After the initial casting process, CNC machines remove excess material and smooth surfaces, ensuring every part matches your design.

You can rely on CNC machining to correct imperfections that naturally occur during casting. For example, it eliminates burrs and sharp edges, leaving a flawless finish. This process also allows you to create intricate features that die casting alone cannot achieve.

Tip: CNC machining ensures that aluminum die-cast parts meet the highest standards of accuracy, making them ideal for industries like automotive and aerospace.

Meeting tight tolerances for OEM aluminum components

Tight tolerances are essential for OEM aluminum die casting. CNC machining ensures that every component adheres to these strict requirements. By following pre-programmed instructions, the machine produces parts with consistent dimensions, even for complex designs.

When you need aluminum components for OEM applications, precision becomes non-negotiable. CNC machining guarantees that each part fits perfectly into its assembly. This reduces the risk of malfunctions and improves overall product reliability.

For instance, if you’re manufacturing engine covers or brackets, CNC machining ensures that every piece aligns seamlessly with other parts. This level of accuracy helps you meet industry standards and customer expectations.

Ensuring repeatability and quality in die-cast parts

Repeatability is crucial when producing large quantities of die-cast parts. CNC machining excels at delivering consistent results, ensuring that every component matches the original design. You can depend on this process to maintain quality across multiple production runs.

Real-time monitoring systems in CNC machines further enhance repeatability. These systems detect deviations and make adjustments to keep operations on track. As a result, you avoid defects and maintain high standards of quality.

Fun Fact: CNC machining allows manufacturers to produce identical parts with minimal waste, making it a cost-effective solution for OEM aluminum die casting.

By combining CNC machining with aluminum die casting, you achieve precision, repeatability, and quality, ensuring your products stand out in competitive markets.

Quality Assurance Practices in CNC Machining

Inspection techniques such as coordinate measuring machines (CMM)

Inspection is a critical step in ensuring the precision of CNC-machined parts. One of the most effective tools for this is the coordinate measuring machine (CMM). You can use a CMM to measure the dimensions of a part with extreme accuracy. It works by using a probe to touch various points on the part’s surface, creating a detailed map of its geometry.

CMMs help you verify that every part matches the original design. For example, if you’re producing components for OEM aluminum die casting, a CMM ensures that each piece meets the required tolerances. This level of precision reduces the risk of defects and ensures compatibility with other parts.

Tip: Regularly calibrate your CMM to maintain its accuracy and reliability.

Process monitoring to ensure adherence to specifications

Monitoring the machining process in real time is essential for maintaining quality. Advanced CNC machines come equipped with sensors that track variables like cutting speed, tool wear, and temperature. These systems alert you to any deviations from the programmed specifications.

For instance, if you’re machining parts for OEM aluminum die casting, process monitoring ensures that every component adheres to the required standards. This reduces the likelihood of errors and minimizes material waste. By keeping a close eye on the process, you can maintain consistent quality across all production runs.

Fun Fact: Some CNC machines use AI to predict potential issues before they occur, further enhancing precision.

Continuous improvement through data analysis

Data analysis plays a key role in improving the quality of CNC machining over time. By collecting data from each production run, you can identify patterns and areas for improvement. For example, analyzing tool wear data might help you optimize tool replacement schedules, reducing downtime and improving efficiency.

When producing parts for OEM aluminum die casting, data analysis helps you refine your processes to achieve even tighter tolerances. This ensures that your products remain competitive in the market. By continuously improving, you can deliver higher-quality parts while reducing costs.

Note: Use software tools to automate data collection and analysis for more accurate insights.

CNC machining transforms how you manufacture spare parts. It uses automation and advanced technology to deliver unmatched precision, ensuring every component meets tight tolerances. You can rely on this process to produce consistent, high-quality results, even for intricate designs.

Tip: Industries like aerospace and automotive depend on CNC machining to reduce defects and improve reliability.

By adopting CNC machining, you enhance efficiency, minimize waste, and meet demanding specifications. This makes it an indispensable tool for industries requiring precision and consistency.

FAQ

1. What industries benefit the most from CNC machining?

CNC machining is widely used in aerospace, automotive, electronics, and medical industries. You can rely on it to produce precise components for complex designs, ensuring reliability and performance in critical applications.

2. How does CNC machining reduce production costs?

It minimizes material waste and defects by following exact specifications. You save money by avoiding rework and optimizing raw material usage. This efficiency makes CNC machining cost-effective for large-scale production.

3. Can CNC machines handle custom designs?

Yes, CNC machines excel at creating intricate and custom designs. You can program them to produce unique geometries and tight tolerances, ensuring compatibility with specialized requirements.

4. What materials work best with CNC machining?

Aluminum, steel, titanium, and plastics are commonly used. You should choose materials based on your application’s needs, such as durability, weight, or machinability.

5. How do real-time monitoring systems improve precision?

These systems track variables like tool wear and cutting speed. They alert you to deviations and make adjustments to maintain accuracy, ensuring consistent quality across production runs.