How Can Cast Aluminum Die Casting Help Lower Carbon Footprints?

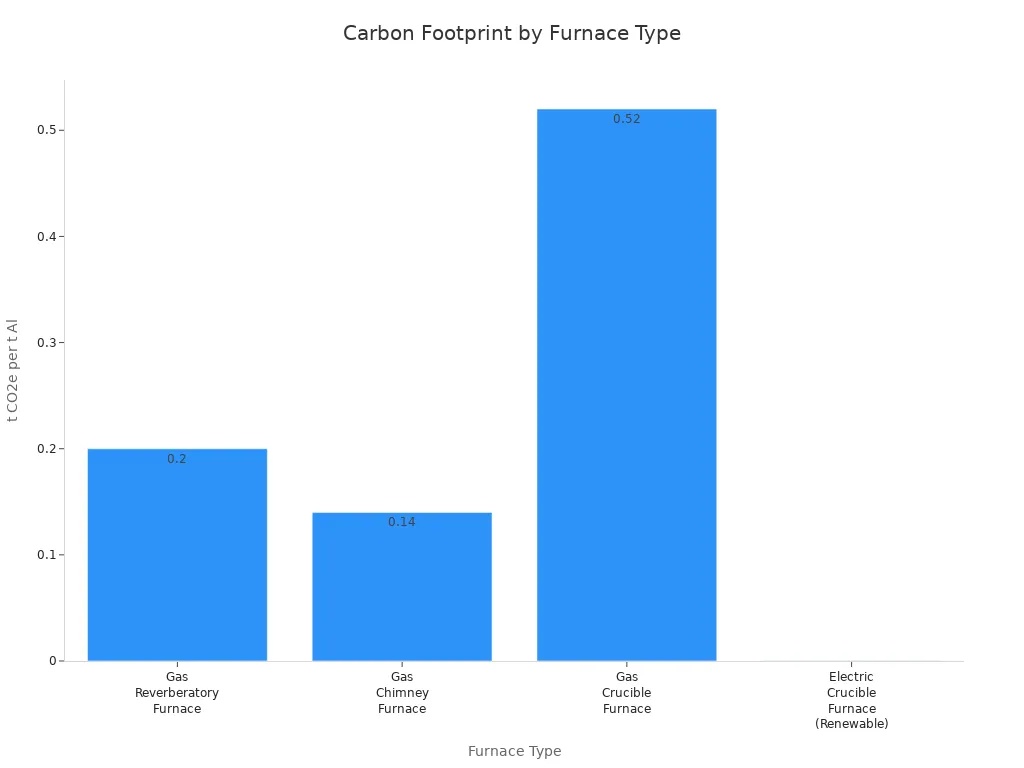

You can see how Cast Aluminum die casting makes a real difference for the environment. When you look at the numbers, electric crucible furnaces powered by renewable energy cut emissions dramatically compared to other methods.

| Furnace Type | Carbon Footprint (t CO2e/t Al) |

|---|---|

| Gas Reverberatory Furnace | 0.2 |

| Gas Chimney Furnace | 0.14 |

| Gas Crucible Furnace | 0.52 (up to 0.72 with oil) |

| Electric Crucible Furnace (Renewable Energy) | 0.0003 |

You help lower your carbon footprint, whether you work in Telecommunication or other Industries Served, by choosing sustainable manufacturing.

Key Takeaways

- Choosing cast aluminum helps lower carbon footprints by using renewable energy in production, significantly reducing emissions.

- Recycling cast aluminum saves about 95% of the energy needed for new aluminum, making it a sustainable choice that conserves resources.

- Using lightweight cast aluminum parts in vehicles improves fuel efficiency and reduces emissions, benefiting both the environment and your wallet.

Cast Aluminum Recyclability and Resource Conservation

High Recyclability of Cast Aluminum

You might not realize it, but cast aluminum stands out as one of the most recyclable materials in manufacturing. You can recycle it over and over again without losing its strength or quality. This makes it a top choice for industries that care about sustainability. When you compare cast aluminum to other metals, you see some big advantages:

- Aluminum can be recycled indefinitely without losing its properties.

- Recycling aluminum saves about 95% of the energy required for primary production.

- Recycling copper saves about 85% of the energy compared to extracting it from virgin ore.

You benefit from this high recyclability because it means less waste and more efficient use of resources. The process also depends on several factors, such as the chemical composition of aluminum alloys, the recycling methods used, and the quality of collection and sorting systems. If you have a strong collection and sorting infrastructure, you get cleaner scrap and higher-quality recycled aluminum. Poor systems can lead to contamination, which lowers the value and usefulness of the recycled material.

Use of Recycled Aluminum in Die Casting

You might be surprised to learn how much recycled aluminum goes into die casting. In North America, about 95% of aluminum die castings come from recycled material. This high percentage shows how committed the industry is to resource conservation. When you choose cast aluminum parts, you support a system that keeps valuable materials in use and out of landfills.

Tip: By choosing products made with recycled aluminum, you help reduce the demand for new raw materials and support a more circular economy.

Impact on Raw Material and Energy Savings

When you use recycled aluminum instead of new, or “primary,” aluminum, you make a huge impact on energy use and emissions. Producing aluminum from recycled sources only takes about 5% of the energy needed for new aluminum. That means you save about 14,000 kilowatt-hours of energy for every ton of recycled aluminum used. This energy savings leads to much lower carbon emissions. For example, the carbon dioxide emissions from recycling are only about 2% of those from making new aluminum. If you look at the numbers, producing one ton of primary aluminum creates about 14.98 tons of CO2e, while recycled aluminum only produces 0.32 tons.

You can see that using recycled cast aluminum in die casting is one of the most effective ways to lower your carbon footprint. You save energy, reduce emissions, and help conserve natural resources—all by making a simple choice in materials.

Cast Aluminum Energy Efficiency and Emissions Reduction

Energy-Efficient Die Casting Processes

You might wonder how die casting can help save energy. Today’s die casting machines use smart technology to cut down on power use. For example, some machines let you turn the hydraulic pump motor on and off, so you only use energy when you need it. This simple change can make a big difference in your energy bills.

Manufacturers also use more recycled and reclaimed metals in their processes. This step not only saves resources but also lowers the energy needed to make new parts. Automation and new material science help boost efficiency even more. You see fewer mistakes, less waste, and a smoother production line.

Here are some of the most energy-efficient technologies used in cast aluminum die casting:

- Machines with on-demand hydraulic pump motors

- Use of recycled and reclaimed metals

- Advanced automation for better control and less waste

- Smart cooling and induction heating systems

- Design software that helps use just the right amount of metal

Note: By improving the melting and heating steps, foundries can save up to 20% on energy. Less energy use means fewer emissions, which is great for the planet.

Lightweight Components Lowering End-Use Emissions

When you choose cast aluminum parts, you help make products lighter. This matters a lot in cars, trucks, and even electric vehicles. Lighter vehicles need less energy to move, so they use less fuel or battery power. That means you see lower emissions every time you drive.

- Lightweight aluminum cuts down the energy needed for movement.

- Engines work less, so you get better fuel efficiency.

- Aluminum parts can improve aerodynamics, which reduces drag.

Let’s look at electric vehicles. Using cast aluminum lets you build strong, single-piece parts. These parts keep the car light but tough. You get better range, improved safety, and a smoother ride. Lighter cars also handle better, especially when turning or stopping.

| Benefit of Lightweight Cast Aluminum | Impact on Vehicles |

|---|---|

| Reduces overall weight | Increases fuel or battery efficiency |

| Maintains strength | Improves safety and crash performance |

| Enables single-piece construction | Lowers assembly time and boosts reliability |

Tip: Every pound you save in a vehicle can lead to real savings at the pump or longer battery life.

Durability and Extended Product Lifespan

You want products that last. Cast aluminum delivers on that promise. It stands up to weather, rust, and daily wear. Many cast aluminum products, like outdoor furniture, can last 15 to 20 years or even longer. You spend less time and money on repairs or replacements.

- Cast aluminum products are solid and long-lasting.

- They need little maintenance and resist rust and wind.

- Choosing cast aluminum is a smart investment for the long term.

Because these parts last so long, you don’t have to replace them as often. This means you use fewer raw materials and create less waste over time. The natural resistance to corrosion helps keep products in use and out of landfills. When you look at the big picture, this durability leads to lower carbon emissions across the entire product life cycle.

Note: Long-lasting products help you shrink your carbon footprint by cutting down on waste and saving resources.

Real-World Impact of Cast Aluminum in Sustainable Manufacturing

Automotive Industry Applications

You see cast aluminum making a big difference in cars and trucks. When you use cast aluminum for parts like transmission cases, engine blocks, and control arms, you help vehicles lose weight. Lighter cars use less fuel and produce fewer emissions. Many manufacturers now choose alloys with a carbon footprint below 4.0 kg CO2 per kilo aluminum. Some companies even aim for a 25% reduction in emissions. You get better fuel economy and help the planet at the same time.

- Common cast aluminum auto parts:

- Transmission cases

- Cylinder tops

- Engine blocks

- Control arms

- Supporting frames

By switching to cast aluminum, you help vehicles run cleaner and more efficiently.

Electronics and Other Key Sectors

You find cast aluminum in electronics, too. Heat sinks and housings made from recycled aluminum keep devices cool and last longer. About 90% of cast aluminum in electronics comes from recycled content. This saves up to 95% of the energy compared to making new aluminum. You also see cast aluminum in aircraft avionics, consumer electronics, and renewable energy systems. These products stay light, strong, and energy-efficient.

| Application | Impact on Sustainability |

|---|---|

| Electronics Heat Sinks | Better heat management, longer life, less waste |

| Aircraft Avionics Housing | Lightweight, durable, less material used |

| Consumer Electronics | Lower energy use, reduced carbon footprint |

Contribution to a Circular Economy

You play a role in the circular economy when you choose cast aluminum. The die casting process uses up to 95% recycled materials and produces less waste than other methods. Recycling aluminum saves about 95% of the energy needed for new production. One third of all aluminum comes from recycled scraps, which means fewer raw materials get used. Life Cycle Assessments show recycled aluminum has the lowest global warming potential and fossil fuel depletion. You help keep materials out of landfills and support a cleaner future.

Choosing cast aluminum supports a cycle of reuse, energy savings, and lower emissions.

You can see how Cast Aluminum die casting helps you lower your carbon footprint. Check out these key benefits:

| Environmental Benefit | How It Helps You and the Planet |

|---|---|

| Recyclability | Keeps materials in use, reduces waste |

| Energy Efficiency | Cuts power use, lowers emissions |

| Durability | Makes products last longer, saves resources |

You support a cleaner future every time you choose Cast Aluminum.

FAQ

How does using recycled aluminum help the environment?

You save energy and cut emissions when you choose recycled aluminum. This choice keeps materials out of landfills and supports a cleaner planet.

Recycling aluminum uses about 95% less energy than making new aluminum.

Can cast aluminum parts be recycled again after use?

Yes! You can recycle cast aluminum parts many times. The metal keeps its strength and quality, so nothing goes to waste.

Why do industries prefer cast aluminum for sustainable manufacturing?

You get lightweight, strong, and durable parts with cast aluminum. These features help lower energy use and reduce your carbon footprint in many industries.