Achieving High Precision with Die Casting CNC Machining Spare Parts

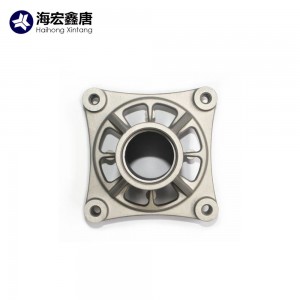

Precision plays a vital role in manufacturing die casting CNC machining spare parts, especially in industries like automotive. You rely on these parts to ensure your vehicle operates smoothly and safely. Achieving high precision can be challenging due to factors like material properties and machining complexities. These challenges directly affect product performance and reliability. NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD excels in producing die casting CNC mechaning spare parts by combining advanced technology with rigorous quality checks. Their ability to deliver precision and casting provide OEM services sets them apart as a trusted industry leader.

Key Takeaways

- Choose materials like aluminum that are strong, light, and easy to shape for better die casting results.

- Check and fix tools often to stop damage and keep quality steady in making parts.

- Adjust CNC machines regularly to stay accurate and avoid expensive mistakes in spare parts.

- Use coolants or other methods to manage heat and stop problems during machining.

- Try advanced tools and software to work with tricky shapes and make detailed designs perfectly.

Material Selection and Compatibility

Choosing the right materials for die casting CNC machining spare parts

Selecting the right materials is the foundation of precision manufacturing. You need materials that can withstand high pressure during the die casting process. Aluminum is often the preferred choice because it is lightweight, durable, and resistant to corrosion. These properties make it ideal for automotive applications, where strength and reliability are critical.

When choosing materials, you should also consider their machinability. Materials that are easy to machine reduce production time and ensure consistent quality. For example, aluminum alloys offer excellent machinability, allowing for intricate designs and smooth finishes.

Tip: Always prioritize materials that balance strength, weight, and machinability for optimal performance in die casting CNC machining spare parts.

Ensuring material compatibility with CNC machining processes

Material compatibility plays a key role in achieving precision during CNC machining. You must ensure that the chosen material aligns with the capabilities of your CNC machines. For instance, some materials may require specific cutting tools or speeds to avoid deformation or surface imperfections.

Thermal properties of the material also matter. During machining, heat can build up and affect the material’s structure. Aluminum, with its high thermal conductivity, dissipates heat effectively, maintaining dimensional stability.

To ensure compatibility, you should test materials under actual machining conditions. This helps identify potential issues like tool wear or surface defects early in the process.

How NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD ensures superior material quality

NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD prioritizes material quality to deliver high-precision die casting CNC machining spare parts. The company uses premium aluminum alloys that meet strict industry standards. These materials undergo rigorous testing to ensure they can handle high-pressure die casting and CNC machining processes without compromising quality.

The company also invests in advanced equipment to test material properties like strength, hardness, and thermal conductivity. This ensures that every batch of material is compatible with their CNC machining centers and numerical control machines.

Additionally, NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD employs a team of experts to evaluate material performance. Their in-house testing procedures guarantee that each material contributes to the precision and reliability of the final product.

Note: By focusing on material quality, NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD ensures that their die casting CNC machining spare parts meet the highest standards of durability and performance.

Tool Wear and Maintenance

The impact of tool wear on precision and product quality

Tool wear directly affects the precision of your manufacturing process. As tools degrade, they lose their sharpness, which can lead to uneven cuts and dimensional inaccuracies. This compromises the quality of the final product. For die casting CNC machining spare parts, even minor deviations can result in poor fit or reduced performance.

Worn tools also increase the risk of surface defects, such as rough finishes or burrs. These imperfections not only affect the appearance of the part but may also weaken its structural integrity. Regularly monitoring tool wear helps you maintain consistent quality and avoid costly rework or material waste.

Tip: Always inspect tools for signs of wear, such as chipping or dull edges, to prevent precision issues.

Effective maintenance practices for CNC machining tools

Proper maintenance ensures your tools perform at their best. Start by cleaning tools after each use to remove debris and prevent buildup. Lubricating moving parts reduces friction and minimizes wear. You should also store tools in a dry, organized space to protect them from damage.

Routine inspections are essential. Check for cracks, wear, or misalignment before starting any machining process. Replacing worn tools promptly prevents further damage to your equipment and ensures consistent results.

Creating a maintenance schedule helps you stay proactive. Documenting tool performance and wear patterns allows you to predict when replacements or repairs are needed.

Advanced coatings and materials used to extend tool life

Modern tools often feature advanced coatings that enhance durability. Coatings like titanium nitride (TiN) or diamond-like carbon (DLC) reduce friction and heat buildup during machining. This extends the tool’s lifespan and improves cutting efficiency.

High-performance materials, such as carbide or ceramic, are also popular for CNC machining tools. These materials resist wear and maintain their sharpness longer than traditional steel tools. By investing in coated or high-quality tools, you can reduce downtime and improve the precision of your manufacturing process.

Note: Using advanced tools not only extends their life but also enhances the quality of your die casting CNC machining spare parts.

Machine Calibration and Accuracy

Importance of precise calibration in CNC machining

Precise calibration is the backbone of accuracy in CNC machining. When your machines are properly calibrated, they produce parts that meet exact specifications. This ensures that every component fits perfectly and performs as intended. Calibration eliminates errors caused by misalignment or incorrect measurements, which can lead to costly defects or rework.

In industries like automotive, where precision is critical, even a small deviation can compromise the functionality of a part. For example, die casting CNC machining spare parts must meet tight tolerances to ensure they integrate seamlessly into vehicles. Proper calibration guarantees that these parts maintain their structural integrity and reliability.

Tip: Regularly check your machine’s calibration to maintain consistent quality and avoid unexpected production delays.

Common calibration errors and how to avoid them

Calibration errors often stem from overlooked details. One common mistake is neglecting to account for thermal expansion. Machines generate heat during operation, which can cause components to expand and affect measurements. To avoid this, you should calibrate your machines when they are at operating temperature.

Another frequent issue is using worn or damaged calibration tools. These tools can provide inaccurate readings, leading to errors in the machining process. Always inspect your calibration equipment before use and replace it if necessary.

Environmental factors, such as vibrations or uneven surfaces, can also disrupt calibration. Ensure your machines are installed on stable foundations and operate in controlled environments.

Note: Keeping a detailed log of calibration activities helps you identify patterns and address recurring issues effectively.

Calibration practices at NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD

At NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD, calibration is a meticulous process. The company employs advanced measuring instruments to ensure their CNC machines operate with pinpoint accuracy. Each machine undergoes routine checks to verify alignment, positioning, and tool offsets.

The team also uses temperature-controlled environments to minimize the impact of thermal expansion during calibration. This ensures that their die casting CNC machining spare parts meet the highest standards of precision.

Additionally, NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD follows a strict schedule for calibration. By adhering to this routine, they maintain consistent performance across their 39 CNC machining centers and 15 numerical control machines. Their commitment to precision reflects in the quality and reliability of every part they produce.

Callout: Trust in a manufacturer that prioritizes calibration to deliver parts that exceed your expectations.

Heat Management

How heat affects precision in die casting CNC machining spare parts

Heat plays a significant role in the manufacturing process. It can cause materials to expand, leading to dimensional inaccuracies. When machining aluminum, excessive heat may alter its structure, resulting in surface imperfections or reduced strength. These issues directly impact the precision of die casting CNC machining spare parts.

Heat also affects the tools used in machining. High temperatures can accelerate tool wear, reducing their sharpness and cutting efficiency. This leads to uneven cuts and poor-quality finishes. Managing heat effectively ensures that both the material and tools maintain their integrity during production.

Tip: Monitor temperature levels during machining to prevent heat-related issues and maintain precision.

Strategies for effective heat management during manufacturing

You can adopt several strategies to manage heat during manufacturing. Start by using cutting fluids or coolants. These liquids reduce friction and dissipate heat, keeping the material and tools cool.

Another effective method is optimizing cutting speeds. Slower speeds generate less heat, while faster speeds may require additional cooling measures. Adjusting speeds based on material properties helps maintain thermal stability.

Tool selection also matters. Tools made from heat-resistant materials, such as carbide, perform better under high temperatures. Regularly inspecting and replacing worn tools prevents heat buildup caused by friction.

Callout: Implementing these strategies improves precision and extends the lifespan of your equipment.

The role of cooling systems in maintaining thermal stability

Cooling systems are essential for controlling heat during machining. They circulate coolants to absorb and remove heat from the cutting area. This prevents overheating and ensures consistent performance.

Advanced cooling systems, such as mist or flood cooling, offer targeted solutions. Mist cooling sprays fine droplets onto the cutting surface, while flood cooling provides continuous liquid flow. Both methods effectively manage heat and enhance precision.

At NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD, cooling systems are integrated into their CNC machining centers. These systems maintain thermal stability, ensuring that die casting CNC machining spare parts meet exact specifications.

Note: Investing in reliable cooling systems safeguards your manufacturing process against heat-related challenges.

Handling Complex Geometries

Challenges in machining intricate designs and shapes

Machining intricate designs presents unique challenges. Complex geometries often involve tight tolerances, sharp angles, and curved surfaces. These features demand extreme precision to ensure the final product meets exact specifications. You may encounter difficulties when working with materials that are prone to deformation or heat buildup during machining.

Another challenge arises from tool accessibility. Reaching deep or narrow areas in a part can be difficult, especially when using standard tools. This can lead to uneven cuts or missed details. Additionally, maintaining consistency across multiple parts with intricate designs requires advanced equipment and meticulous planning.

Tip: Always evaluate the design complexity and material properties before starting the machining process.

Tools and techniques for achieving precision in complex geometries

To achieve precision in complex geometries, you need specialized tools and techniques. Multi-axis CNC machines, such as 5-axis systems, allow you to approach the part from multiple angles. This capability ensures accurate machining of intricate features.

Using high-speed cutting tools made from durable materials like carbide or ceramic improves precision. These tools maintain their sharpness, even when machining challenging designs. Employing techniques like trochoidal milling can also help. This method reduces tool stress and improves accuracy by using smaller, circular cutting paths.

Callout: Investing in advanced tools and techniques ensures consistent quality for intricate designs.

Leveraging simulation and software for complex part designs

Simulation software plays a crucial role in handling complex geometries. By using CAD/CAM programs, you can visualize the machining process before production begins. This helps you identify potential issues, such as tool collisions or material wastage, early in the design phase.

Advanced software also allows you to optimize tool paths for maximum efficiency. For example, you can simulate cutting angles and speeds to minimize errors and improve surface finishes. At NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD, simulation tools are integral to producing high-quality die casting CNC machining spare parts. These tools ensure that every part meets the required specifications, no matter how complex the design.

Note: Leveraging simulation software reduces trial-and-error, saving time and resources in the manufacturing process.

Achieving high precision in die casting CNC machining spare parts requires a combination of the right materials, proper tool maintenance, accurate machine calibration, effective heat management, and advanced techniques for handling complex geometries. By following these strategies, you can ensure consistent quality and performance in your manufacturing process.

NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD demonstrates an unwavering commitment to precision and quality. Their expertise, advanced technology, and rigorous quality checks make them a trusted partner for high-performance spare parts.

Adopting these best practices will help you produce reliable products that meet industry standards and exceed customer expectations.

FAQ

1. What industries benefit the most from die casting CNC machining spare parts?

Die casting CNC machining spare parts are widely used in automotive, aerospace, and electronics industries. These parts ensure high precision and durability, making them ideal for applications requiring tight tolerances and reliable performance.

Tip: Always choose a manufacturer experienced in your industry for the best results.

2. How does CNC machining improve the precision of spare parts?

CNC machining uses computer-controlled tools to create parts with exact dimensions. This process eliminates human error and ensures consistent quality across all components. It also allows for intricate designs and tight tolerances.

3. Why is aluminum a popular material for die casting spare parts?

Aluminum is lightweight, strong, and corrosion-resistant. It also has excellent thermal conductivity, making it ideal for high-pressure die casting. Its machinability allows for precise and complex designs.

Note: Aluminum alloys are commonly used for automotive applications due to their durability and reliability.

4. How can you ensure the quality of die casting CNC machining spare parts?

You can ensure quality by choosing a manufacturer with advanced equipment, strict quality checks, and certifications like ISO 9001. Regular inspections and material testing also help maintain high standards.

5. What makes NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD a trusted manufacturer?

NINGBO HAIHONG XINTANG MECHANICAL CO.,LTD combines advanced technology, premium materials, and rigorous quality checks. Their expertise in aluminum die casting and CNC machining ensures precision and reliability in every part they produce.

Callout: Contact them today to experience their exceptional service and high-quality products.