How Aluminum Die Casting Parts Elevate Quality Standards in the Automotive Industry

Aluminum die casting plays a pivotal role in enhancing quality standards within the automotive industry. This manufacturing process effectively addresses challenges such as defects and mechanical properties. Notably, more than 70% of vehicle castings utilize die casting, leading to remarkable improvements in dimensional accuracy and surface finish. Robotic integration further reduces casting defect rates to below 2%, ensuring reliability in automobile components.

Key Takeaways

- Aluminum die casting significantly reduces defects in automotive parts, leading to higher quality and reliability.

- This process enhances mechanical properties, providing components with outstanding durability and a superior strength-to-weight ratio.

- Die casting improves production efficiency by minimizing material waste and reducing lead times, ultimately lowering costs.

Addressing Defects in Automobile Parts

Common Defects in Automotive Manufacturing

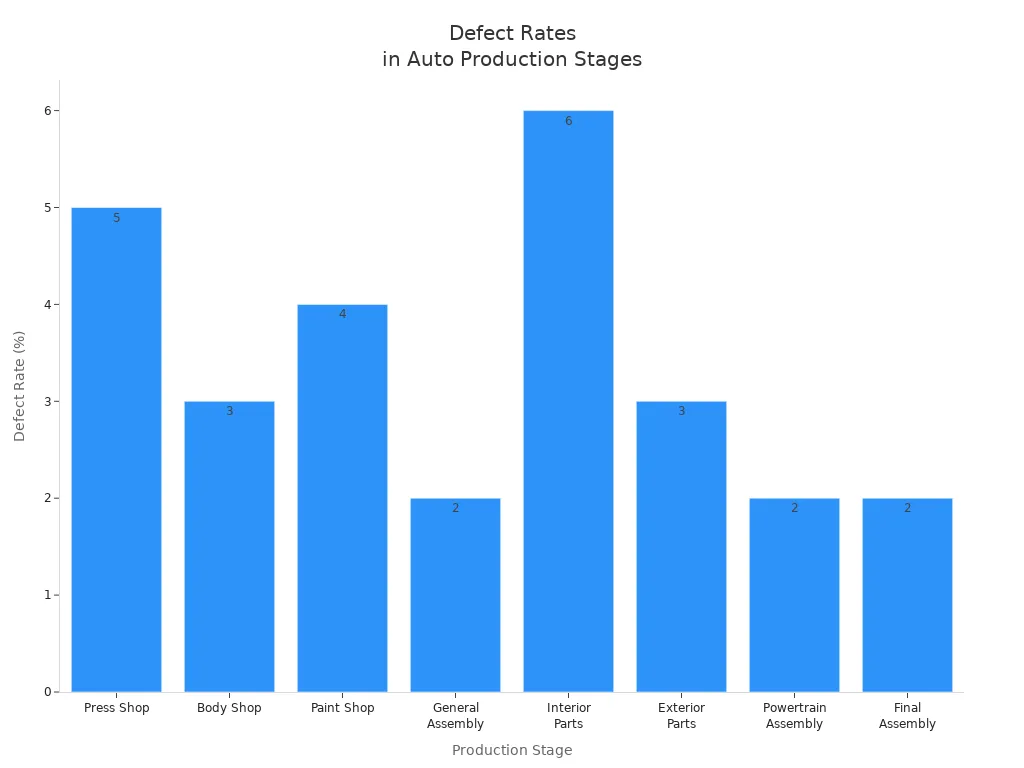

Automotive manufacturing often encounters various defects that can compromise the quality and safety of vehicles. Understanding these defects is crucial for manufacturers aiming to enhance their production processes. Common defects include:

- Dents and Deformations: Often found in the press shop, these imperfections can affect the structural integrity of parts. Approximately 5% of parts may exhibit such defects.

- Poor Welding Joints: In the body shop, misalignments and fitting issues can lead to weak connections, impacting up to 3% of vehicles.

- Paint Defects: Bubbles, scratches, and uneven coverage can occur in the paint shop, affecting around 4% of vehicles.

- Loose Connections: General assembly can see issues like misaligned parts and damaged components, impacting up to 2% of vehicles.

- Fit Issues in Interior Parts: Problems such as premature wear and control malfunctions can affect up to 6% of vehicles.

- Exterior Misalignments: Scratches and visible damage can occur, affecting about 3% of vehicles.

- Powertrain Issues: Oil leaks and synchronization problems can impact up to 2% of vehicles.

- Final Assembly Errors: Assembly mistakes and calibration issues can also affect up to 2% of vehicles.

| Stage of Production | Common Defects | Statistics |

|---|---|---|

| Press Shop | Dents, deformations, imperfections in metal sheets | ~5% of parts may exhibit defects |

| Body Shop | Poor welding joints, misalignments, fitting issues | Up to 3% of vehicles affected |

| Paint Shop | Bubbles, scratches, uneven paint coverage | ~4% of vehicles may have paint defects |

| General Assembly | Loose connections, misaligned parts, damaged components | Up to 2% of vehicles affected |

| Interior Parts | Fit issues, premature wear, control malfunctions | Up to 6% of vehicles affected |

| Exterior Parts | Misalignments, scratches, visible damage | ~3% of vehicles affected |

| Powertrain Assembly | Oil leaks, synchronization issues, control failures | Up to 2% of vehicles affected |

| Final Assembly | Assembly errors, incorrect adjustments, calibration issues | Up to 2% of vehicles affected |

How Die Casting Reduces Defects

Aluminum die casting significantly reduces the occurrence of defects in automotive parts. This manufacturing process offers several advantages that enhance quality control.

- Precision and Consistency: Die casting allows for high precision in part dimensions. This precision minimizes the risk of defects such as misalignments and fitting issues. The process ensures that parts fit together seamlessly, reducing the likelihood of assembly errors.

- Reduced Porosity: Research indicates that defects like gas and shrinkage pores often initiate fatigue cracks in automotive components. By utilizing advanced die casting techniques, manufacturers can achieve lower porosity levels in their products. A study revealed that addressing large micropores near edges can significantly improve the mechanical properties of automotive wheels.

- Enhanced Surface Finish: The die casting process produces components with superior surface finishes. This quality reduces the chances of paint defects and enhances the overall aesthetic appeal of the vehicle.

- Quality Control Measures: Effective quality control measures are integral to the die casting process. These measures include:

- Control of raw materials to ensure high-quality inputs.

- Mold temperature control to reduce defects during casting.

- Careful selection of mold design and materials based on specific part requirements.

By implementing these strategies, manufacturers can achieve defect rates significantly lower than those associated with traditional manufacturing methods. For instance, studies show that high-pressure die casting (HPDC) often faces challenges with defects like pores and hot tears due to the complexity of casting shapes. In contrast, aluminum die casting provides a more controlled environment, leading to higher quality outputs.

Enhancing Mechanical Properties in Automotive Components

Importance of Mechanical Properties in Automotive Parts

Mechanical properties play a crucial role in the design and functionality of automotive components. Engineers prioritize these properties to ensure vehicles can withstand various stresses and strains during operation. Key mechanical properties include:

- Tensile Strength: This property measures how much force a material can withstand while being stretched or pulled. It is vital for components that experience tension, such as suspension parts.

- Ductility: Ductility refers to a material’s ability to deform under tensile stress. This characteristic is essential for parts that must absorb energy during impacts, enhancing safety.

- Fatigue Resistance: This property indicates how well a material can endure repeated loading and unloading cycles without failing. It is critical for components subjected to constant stress, such as engine parts.

Understanding these mechanical properties allows engineers to design structures that resist deformation and failure under various loads. In the automotive industry, selecting materials based on their mechanical properties ensures stability and safety in vehicle performance.

Benefits of Aluminum Die Casting on Mechanical Strength

Aluminum die casting significantly enhances the mechanical strength of automotive components compared to traditional manufacturing methods. The advantages of this process include:

- Outstanding Durability: Die casting produces parts with exceptional durability, increasing the longevity of vehicle components. High-strength wheels manufactured through this method can resist harsh driving conditions.

- Remarkable Strength-to-Weight Ratio: Aluminum die castings provide a superior strength-to-weight ratio, enhancing overall performance in automotive applications. Lighter components lead to increased fuel efficiency and reduced emissions.

- Complex Part Production: The high strength of aluminum die castings allows for the production of intricate parts that can withstand demanding conditions. This capability enables manufacturers to create components that meet specific performance requirements.

- Design Versatility: Die casting offers unrivaled design flexibility, enabling intricate shapes that traditional methods struggle to achieve. This versatility allows for the development of practical and visually appealing automotive components.

The minimum mechanical property requirements for key automotive parts, such as engine blocks and transmission housings, highlight the importance of aluminum die casting. The following table summarizes these requirements:

| Component | Material | Key Properties |

|---|---|---|

| Engine Blocks | Aluminum | Lightweight, excellent thermal conductivity, high strength, corrosion resistance |

| Transmission Housings | Aluminum | Reduced weight, improved thermal conductivity, increased corrosion resistance |

In addition to these benefits, aluminum die cast parts exhibit excellent corrosion resistance compared to steel or plastic alternatives. The following table illustrates this comparison:

| Material | Corrosion Resistance | Notes |

|---|---|---|

| Aluminum | Exceptional | Rust-proof due to low iron content, can corrode under certain conditions |

| Steel | Poor | Prone to rusting when exposed to moisture |

| Plastic | None | Does not corrode but lacks structural integrity compared to aluminum |

Overall, aluminum die casting not only improves mechanical properties but also contributes to the overall performance and safety of automotive components.

Improving Production Efficiency in the Automobile Sector

Challenges in Production Efficiency

Automotive manufacturers face several challenges that hinder production efficiency. These challenges include long lead times, high material waste, and escalating labor costs. Traditional manufacturing techniques often lead to bottlenecks, which slow down the production process. For instance, the complexity of assembly lines can create delays, impacting overall productivity.

To address these issues, manufacturers have explored various strategies. Some effective approaches include:

- Single-piece flow: This method eliminates bottlenecks and reduces lead times.

- Cellular manufacturing: This strategy increases overall flow and efficiency.

- Quick changeover (SMED): This technique enhances flexibility and responsiveness.

Streamlining Processes with Die Casting

Aluminum die casting offers significant advantages in improving production efficiency. This process minimizes material waste, which directly reduces costs. It also allows for high production rates, leading to increased productivity and lower labor costs. The exceptional dimensional accuracy and surface finish achieved through die casting reduce the need for additional machining, saving both time and money.

Moreover, integrating automation in die casting machines reduces work-in-progress transit time, leading to shorter lead times. Cycle time optimization increases Overall Equipment Effectiveness (OEE), allowing manufacturers to fulfill more orders without extending plant hours. As a result, aluminum die casting not only enhances product quality but also contributes to substantial cost savings.

Aluminum die casting plays a crucial role in elevating quality standards in the automotive industry. It effectively addresses defects, enhances mechanical properties, and improves production efficiency. The process produces lightweight components that enhance vehicle performance and fuel efficiency. Additionally, aluminum die casting supports sustainable practices, making it a preferred choice for modern automobile manufacturing.

FAQ

What are the advantages of aluminum die casting in automotive manufacturing?

Aluminum die casting offers high precision, reduced defects, and improved mechanical properties, enhancing overall vehicle performance and safety.

How does aluminum die casting contribute to sustainability?

This process minimizes material waste and utilizes eco-friendly practices, supporting manufacturers in reducing their environmental impact while producing high-quality components.

Can aluminum die casting be customized for specific automotive needs?

Yes, manufacturers like HHXT provide customized aluminum die casting solutions tailored to meet unique specifications and requirements for various automotive applications.